LEVEL GAUGE

By KENCOLevel gauges are cost-effective industrial meters to sight liquid level indication for process tanks operating at low pressures. Simple and low-cost, sight flow indicators also allow operators to observe the colour and clarity of process fluids through a window. The ability to see what is happening inside a tank is invaluable to process operators.

A primary standard tank level gauge consists of a toughened continuous section of borosilicate glass tube which is connected at both the top and bottom to an isolation valve. The advantages include greater durability in severe environments and the ability to withstand high temperatures and pressure. They are designed to be easily read from a distance, and they can be used in addition to a switch in a system. There is little maintenance required, and all repairs can be done without disturbing the system. They can also be customised for extreme applications.

Process observation equipment falls into two major categories: sight glasses, also called sight glass windows, which are used on process vessels, and sight flow indicators, which are used in process pipelines.

Full View Sight Flow Indicators are devices used to observe the flow of liquids in a piping system. 360 visibility provides convenient viewing from any angle. Designed for vertical applications. Threaded and flanged connections are available in a variety of sizes to match the diameter of the pipe being used. A wide range of end plate materials are available. Units can be made with any overall length if additional visibility is required. Full View Sight Flow Indicators are used in low-pressure applications. Maximum pressure allowable will vary with temperature and size.

Armored Sight Flow Indicators are used to observe the flow of liquids in a piping system. A rigid steel housing surrounds the sight tube and provides additional strength and protection from mechanical impact. Threaded and flanged connections are available in a variety of sizes to match the diameter of the pipe being used. A wide range of housing materials is available. Units can be made with any overall length if additional visibility is required. Wetted materials consist of glass and the connection end plates. Recommended for low pressure vertical or horizontal applications. Maximum pressure allowable will vary with temperature and size.

They are easy to read from a distance and can be used in addition to a switch or alarm in a system. There is little maintenance required, and all repairs can be done without disturbing the system. They can also be customised for extreme applications. Our liquid level gauge & valve specialists are available to answer your product specification questions.

Unlike sight glass windows that don’t have indicating mechanisms, sight flow indicators may have passive components that are set in motion by the flow to indicate flow direction or intensity. If the flow indicator

has indication components, a certain level of flow is required to place them in motion. Flow indicators without indication components are used where observing the characteristics of a process fluid is more important than verifying flow. Because indication components complicate cleaning in hygienic systems, they are rarely used in sanitary applications.

In addition, some flow indicators, called flow meters have a calibrated scale that provides a rough measurement of flow to an observing operator.

Flow indicators can be custom made for large diameter pipes. A cost-saving alternative is to install a standard diameter flow indicator on a smaller pipe running in parallel.

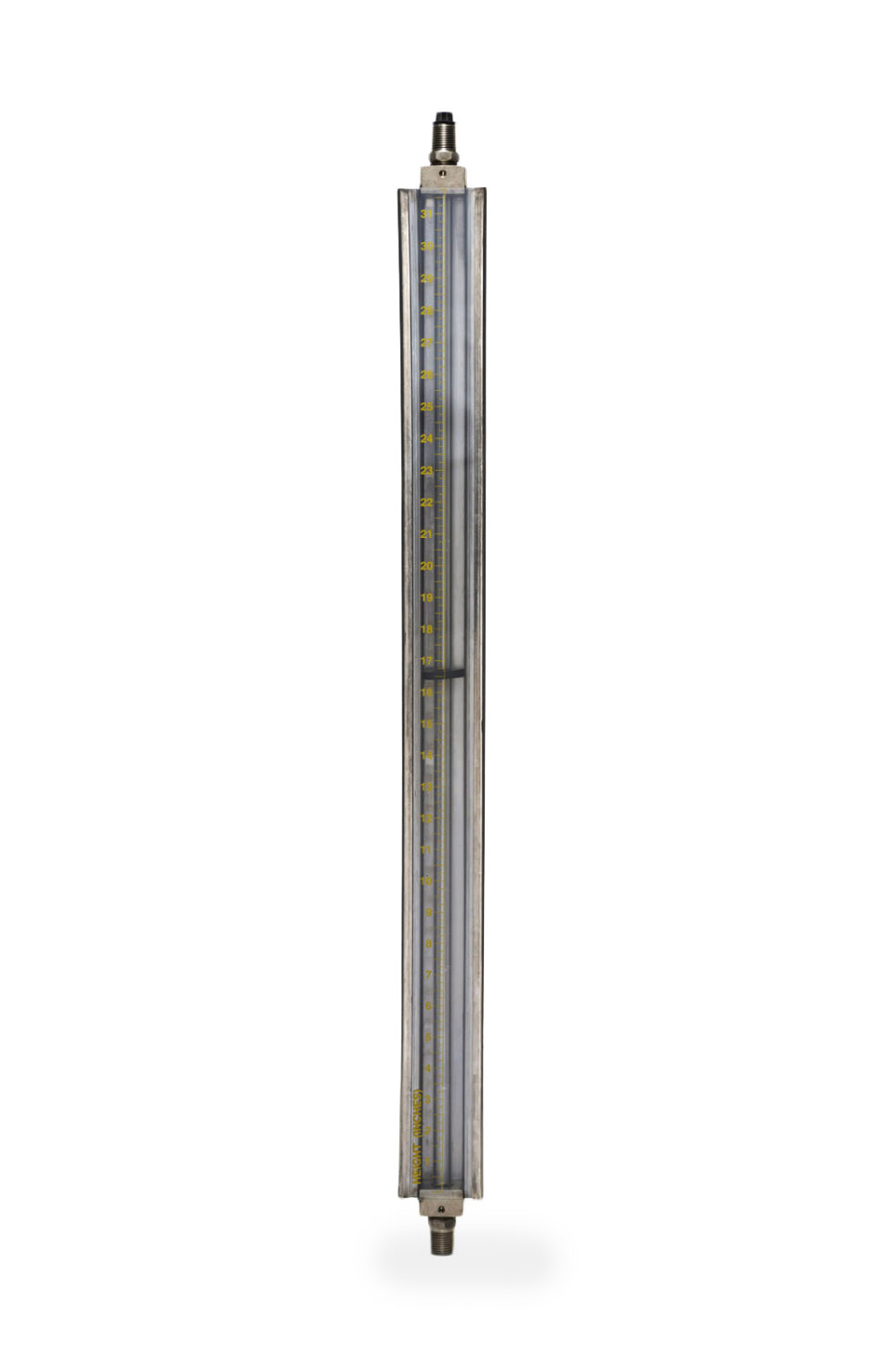

5700 Bulk Tank Gauge

The sight tube of the 5700 Series Level Gauge is completely protected. Three sides of the gauge are protected with a metal frame, while the face of the gauge is protected with a polycarbonate shield. This shield can be custom calibrated to read tank volume or any other calibration. For mounting purposes, a mounting lug is welded to the back of the gauge. The standard sight tube is glass; other sight tube materials are available, along with a wide option of O-ring seals. The gauge is fitted with 1/2″ MNPT x 3/8″ FNPT connections.

Applications

The 5700 Series Gauge provides a visual means for checking the contents of a bulk tank and a means for checking the injection rate of a chemical metering pump. The gauge is designed to operate in low to medium pressure applications up to 500 psig.

17000 Bulk Tank Gauge

The 17000 Gauge functions as a level indicator and also serves as a pump setting gauge. The rate scale can be calibrated in a variety of options, such as GPM, GPH, GPD, LPM, LPH, or LPD. The maximum pump rate for a 12″ gauge section is 25 GPD. The sight tube in the 17000 is 1″ O.D. glass, which makes it ideal for viscous fluids. The top and bottom connection for this gauge is 1″ MNPT.

EPG Environmental Protection Gauge

U.S. Patent Number 5442959

Applications

The Environmental Protection Gauge (EPG) is easy to install. It installs just like tubular glass and is designed to replace your existing tubular glass. It will eliminate glass breakage and stop costly spills. The metal end connection of the gauge inserts into the valve stuffing box thus eliminating two common points for glass breakage:

- Over-tightening of the glass packing

- Breakage of glass at the packing nuts from impact to the gauge