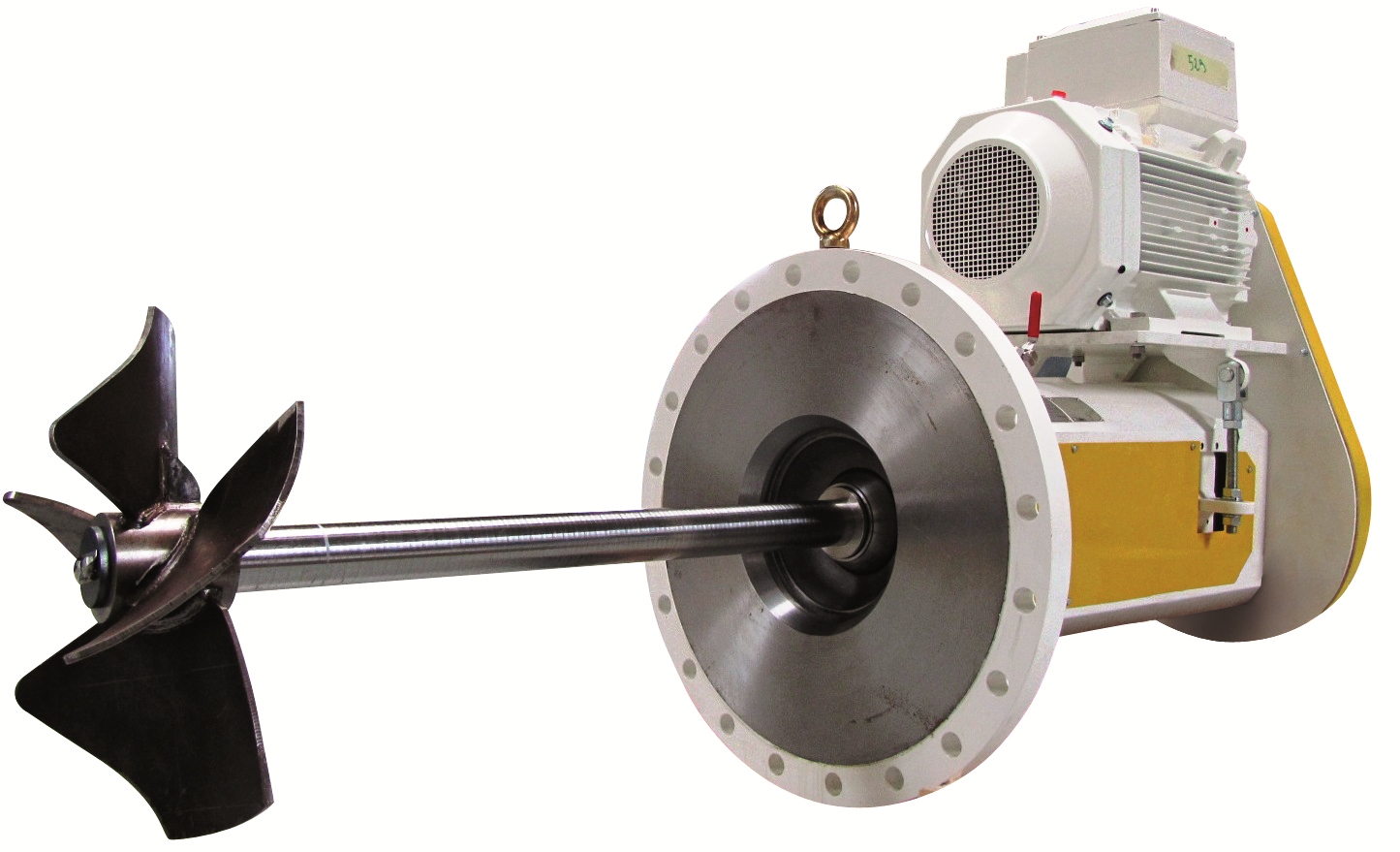

SIDE ENTRY AGITATOR

By MILTON ROYAgitation is an induced motion of the material circularly in a container in the desired way within a container.

The material is agitated by a stirrer or mixer that is made up of a shaft that connects the motor and the impeller.

On the other hand, mixing is the random distribution of materials in different phases into another forming a homogeneous phase.

Examples of processes that use agitation are the blending of two miscible liquids, the dissolving of solids in liquids, and the dispersion of gas in a liquid as fine bubbles, such as oxygen in a suspension of microorganisms for waste-treatment. Other examples include the suspension of the fine solid particle, such as metallic pigments in paint, and the agitation of a fluid to eliminate temperature gradients

Side Entry Agitator Mixer

The Milton Roy Mixing SIDE ENTRY MIXER mounts quickly and easily on the tank flange to deliver the most effective mixing results in an etremely efficient units. The small diameter of the SABRE impeller allows for reduced energy conusmption and easy installation. The Side Entry Mixer is designed for tanks up to 200,000 m3 (1.3 MM Barrels).

Some products must be stored at a warm temperature to be more fluid (vegetable oils, plant extracts, glues) while others must be stocked at low temperatures (beverages, milk).

Taking into account the large volumes of the tanks, the ease of the operation of agitation required, and the inability of the tank storage to support a load on the roof.

Characteristics

- Operating capacity: from 5 m3 to 200 000m3

(1,3 MM barrels) - Rated Power: from 0.37 to 55 kW (10 to 75 Horsepower)

- Rotation Speed: from 200 to 1500 rpm

- SABRE® or HPM® IMPELLERS

- Operating conditions: from -1 to 10 bars ; from 0° to 250°C (482°F)

- TEFC, Ex Proof, IEEE-841 available

- Quick Shut off device

- Carbon Steel

- Single Mechanical Seal