OIL LEVEL CONTROLLER

By KENCOLevel controllers are devices used to sense and maintain levels of liquid, such as oil or water, within a chamber. For example, when the liquid level in the elevated tank is low, an external delivery apparatus or system pumps up supplementary liquid from a secondary tank to supplement it. Once the desired liquid level is attained, the pump will stop.

Oil level controllers work the same way as traditional float switches work, except that they are designed to work with oil instead of water. Oil level sensors use magnetic instead of electrical switches and are completed sealed in a stainless steel or plastic stem.

An oil level controller is an oil level sensor that opens and closes circuits as oil level rise or fall. This action of opening and closing circuits can be used to turn oil pumps on or off automatically. They are typically designed to indicate and to maintain the operating oil level in the engines crankshaft boxes, compressors and gearbox systems.

These devices work in conjunction with an external delivery system that feeds oil to the level controller. As the oil is consumed, the controller provides the amount of oil required via a float-controlled valve. This keeps the oil level constant and at its optimum value.

Combustion engines, compressors, turbines, slide bearings and gears – they all depend on a reliable supply of lubricating oil. An oil level sensor system with reliable components is indispensable for the continuous operation of engines and can determine the lifespan of a compressor. The correct application of oil refilling systems leads to reduce wear and maintenance costs, and pre-programmed oil changes save time and guarantee compliance with the oil change interval requirements.

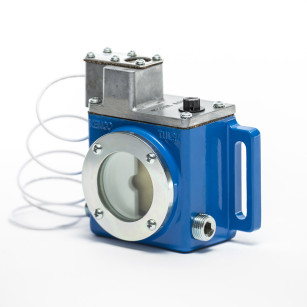

KENCO Oil Level Controllers are designed to maintain the running oil level in the crankcase of stationary engines, compressors, and mechanical lubricator boxes.

The KENCO oil controller works in partnership with an overhead oil supply system which feeds the oil level controller. As the oil is consumed, the oil controller supplies the required amount of oil to maintain the desired level in the crankcase.

The oil controller maintains the appropriate amount of oil in the crankcase using a float controlled valve. The valve automatically opens and closes as oil is needed in the crankcase to provide a constant oil level.

The oil level switch in the KLCE is an electric switch in an explosion proof enclosure, rated for hazardous hydrogen gas environments. The float switch monitors the oil in the crankcase.

The level within the crankcase directly corresponds with the oil level in the oil level controller housing. If the oil level in the crankcase drops 3/4″ past the centerline, the switch will trip sending an alarm.

KLCE Oil Level Controller

The oil level switch in the KLCE is an electric switch in an explosion proof enclosure, rated for hazardous hydrogen gas environments. The float switch monitors the oil in the crankcase. The level within the crankcase directly corresponds with the oil level in the oil level controller housing. If the oil level in the crankcase drops 3/4″ past the centerline, the switch will trip sending an alarm.

Applications

- Hazardous locations where flammable or combustible elements are present.

- Stationary engines and compressors

- Mechanical lubricators

- Pumps

KSHL Oil Level Controller

The Kenco KSHL is constructed with two independent switches, one for high level alarm 3/4″ above centerline and another for low level alarm at 3/4″ below centerline. The oil level switches in the KSHL are electric switches in an explosion proof enclosure, rated for hazardous hydrogen gas environments.

Applications

- Locations where high and low level switches will be wired to separate alarms

- Hazardous locations where flammable or combustible elements are present.

- Stationary engines and compressors

- Mechanical lubricators

- Pumps

KHL Oil Level Controller

The oil level switch in the KHL is an electric switch in an explosion proof enclosure, rated for hazardous hydrogen gas environments. The float switch monitors the oil in the crankcase. The level within the crankcase directly corresponds with the oil level in the oil level controller housing. If the oil level in the crankcase drops or rises 3/4″ past the centerline, the switch will trip sending an alarm.

Applications

- Locations where high and low levels will be monitored by one alarm

- Hazardous locations where flammable or combustible elements are present.

- Stationary engines and compressors

- Mechanical lubricators

- Pumps

K512 Oil Level Controller

The oil level switch in the K512 is a case to ground electric switch contact for non-hazardous locations. The level within the crankcase directly corresponds with the oil level in the oil level controller housing. If the oil level in the crankcase drops past the designated level, the switch will trip sending an alarm.

Applications

- Locations where space is limited

- Non-hazardous locations

- Stationary engines and compressors

- Mechanical lubricators

- Pumps

KSLL Oil Level Controller

The Kenco KSLL is constructed with two independent switches, one for low level alarm 5/8″ below centerline and another for low level alarm at 7/8″ below centerline. The oil level switches in the KSLL are electric switches in an explosion proof enclosure, rated for hazardous hydrogen gas environments. The float switches monitor the oil in the crankcase. The level within the crankcase directly corresponds with the oil level in the oil level controller housing. If the oil level in the crankcase drops past the designated levels, the switches will trip sending an alarm.

Applications

- Locations where 2 low level switches will be wired to separate alarms, tripping at 5/8″ and 7/8″ drops below centerline

- Hazardous locations where flammable or combustible elements are present.

- Stationary engines and compressors

- Mechanical lubricators

- Pumps

KLCM Oil Level Controller

The oil level switch in the KLCM is an electric switch in a CSA approved Class III, Type 4 enclosure. The float switch monitors the oil in the crankcase. The level in the crankcase directly corresponds with the oil level in the oil level controller housing. If the oil level in the crankcase drops 3/4″ past the centerline, the switch will trip sending an alarm.

Applications

- Intrinsically safe applications with an approved safety barrier

- Stationary engines and compressors

- Mechanical lubricators

- Pumps

KLCP Oil Level Controller

The oil level switch in the KLCM is an electric switch in a CSA approved Class III, Type 4 enclosure. The float switch monitors the oil in the crankcase. The level in the crankcase directly corresponds with the oil level in the oil level controller housing. If the oil level in the crankcase drops 3/4″ past the centerline, the switch will trip sending an alarm.

Applications

- Remote or offshore locations with no electric power.

- Stationary engines and compressors

- Mechanical lubricators

- Pumps

507 Oil Level Controller

507 Series Oil Level Controllers automatically monitor and control the amount of oil in the lubricator housing. This keeps all of the working parts including the pump plungers submerged in oil to reduce wear and corrosion. When the level falls below the operational requirement, the low level safety switch will be activated.

Applications

- Lincoln, Premier, and Mega Lubricator Boxes